Mohawk Synthetics with Cobalt

Areas of Ownership:

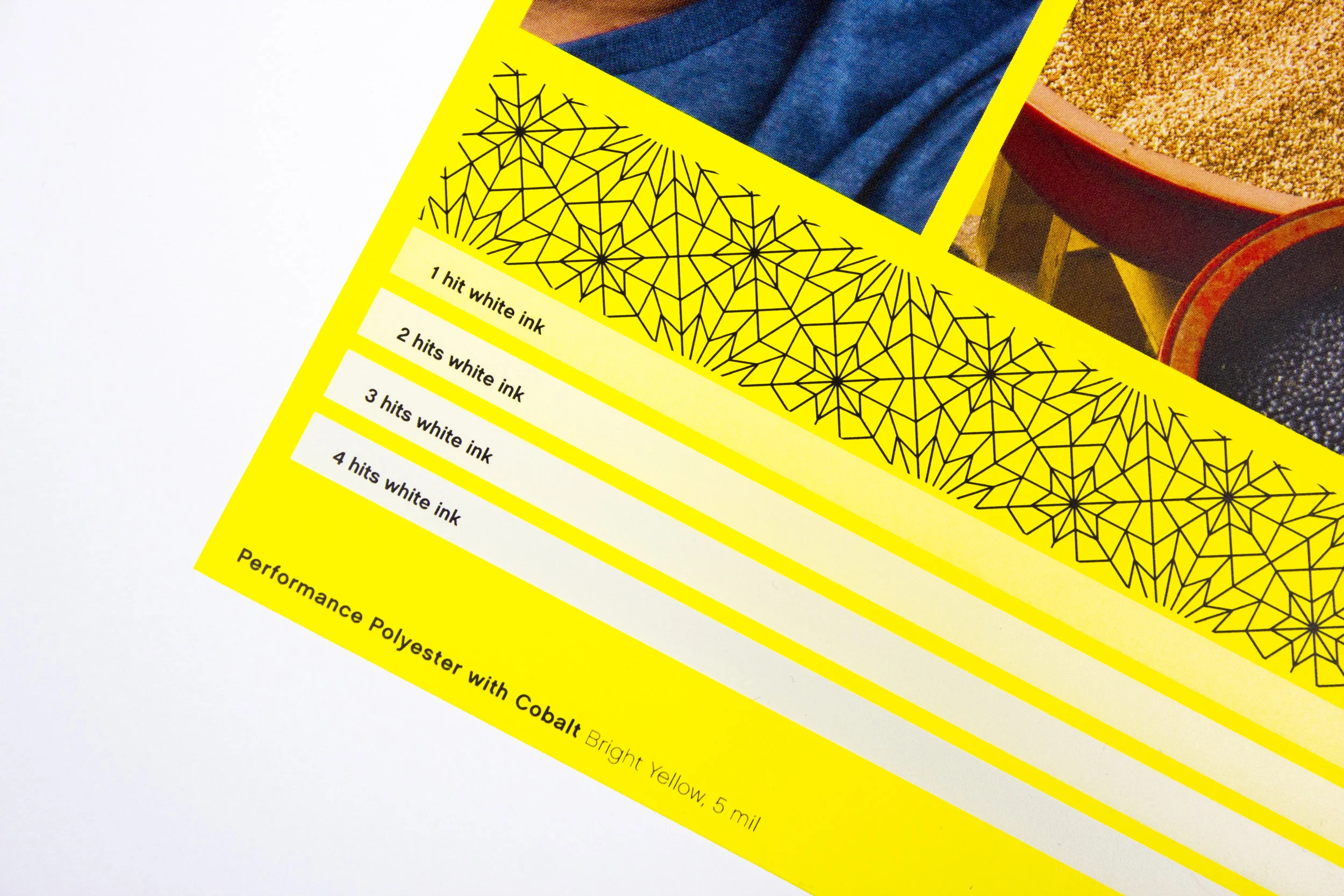

Internal Sample Waterfall

Skills Involved:

Layout Design, Image manipulation, Pre-Press and Production editing, Use of White Ink

Project Summary:

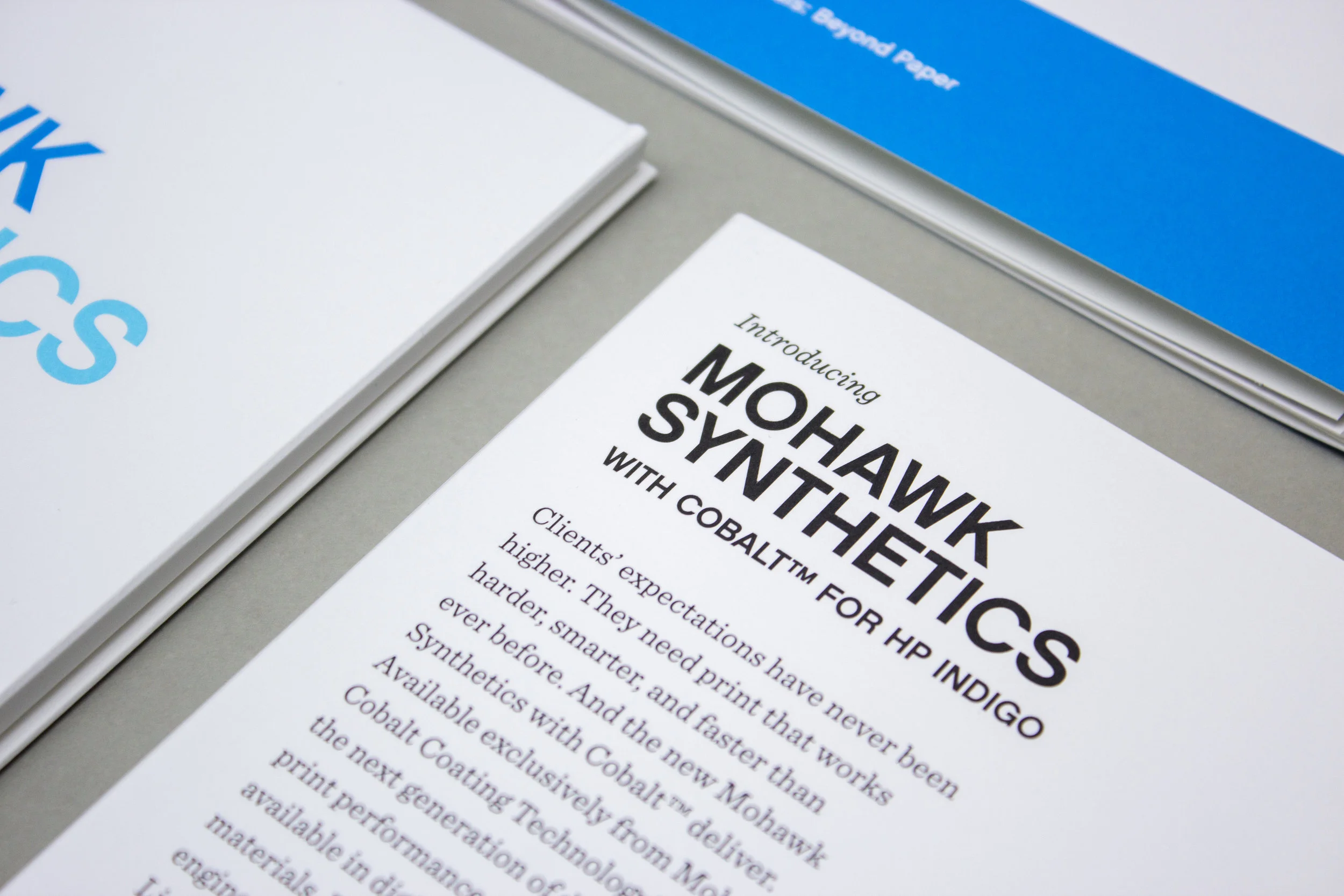

In Spring 2019, Mohawk partnered with Kernow Coatings Limited to produce a high-performance coating for synthetic substrates. Cobalt Coating Technology™ for HP Indigo represents a new benchmark for HP Indigo synthetics print performance.

With guidance from my manager, I created appropriate waterfalls and white ink layers that could be produced at the Mohawk Innovation Center in Albany, NY. Our pressman gave me specs for the pre-press and production process, which gave me an interesting look at the printing process for a non-paper substrate. Later work involved pre-press and production for some of Kernow’s synthetic samples that needed to be adjusted and converted for our press. This was a great project, and a deceptively simple one, to initiate me to pre-press. My next pre-press project, the Mohawk Carnival + Via Line Expansion Kit (below), turned out to be a much bigger learning experience for me.

Mohawk Carnival + Via Line Expansion

Areas of Ownership:

Internal Sample Waterfall

Skills Involved:

Layout Design, Image manipulation, Pre-Press and Production editing, Use of White Ink

Project Summary:

In the early summer of 2019, Mohawk announced a line expansion for their Carnival + Via line of papers, that was specific to digital printing and featured Mohawk’s proprietary i-Tone® surface treatment.

Pre-press for this piece was significantly harder - while Synthetics with Cobalt had it’s own set of issues, the piece was relatively easy to set up and print. Synthetics, like all substrates, stretch and move with the heat of printing, but Synthetics do it in a predicable, manageable way. We were able to reduce trapping with relative ease on the Cobalt Kit. However, the uncoated and Vellum textured Carnival + Via papers lead to some interesting characteristics that sent me down a rabbit hole of pre-press editing. What worked on 80C Via Red didn’t work with 80C Via Deep Blue. What worked on 80C Via Deep Blue didn’t work with 100C Via Deep Blue. White ink - a brilliant invention, but not without it’s quirks.

The end result was a true passion project for me. While not perfect by any means, we were able to overcome the issues at hand and provide the market with a truly unique printing experience.